Spyderco Knives

Spyderco knives are immediately recognizable for their smart, ground-breaking designs that exceed beyond what you discover from other brands.

25 Best Spyderco Knives

For over 40 years, Spyderco knives have been a popular option for knife enthusiasts from worldwide, and it’s easy to see why.

From being the first to innovate features that are standard on almost all knives today, to producing new purpose-driven styles that make your jobs easier and more efficient.

Spyderco has actually never stopped producing remarkably practical knives that are must-haves for any collection.

How Spyderco Started?

Spyderco’s founder Sal Glacier and his wife Gale transformed an old bread delivery truck into a motor home and traveled to the show.

When they were more successful, they graduated truckloads of bread and trailers. It was founded in Golden in November 1978.

Today, Spyderco Knives has lots of designs to select from based upon your jobs and requirements, but there a few that truly stand apart: If you’re interested in a Spyderco knife however are uncertain of where to start, then let us recommend the Spyderco Endura.

Spyderco Endura knives are amongst the company’s initial bestsellers and they come packed with all the heft and power you need from an exceptional folding knife, however at an affordable cost point.

Following are considered best among all knives made by Spyderco which are also currently on sale with us along with other deals mentioned under:

Spyderco Fixed Blade Knives

These knives are suitable to be used for digging, cutting, and many more tasks; many of these knives are manufactured using the VG-10 stainless steel blades.

The strength of these blades is commendable and withstands high compression and pressure. The functionality is superior and provides optimum protection to excessive wear and tear.

Spyderco Throwing Knives

Throwing knives are designed precisely to cater the sole purpose of throwing tactfully.

Unlike other ordinary knives, these knives need sufficient strength and efforts to hit the target exactly across short or long distance.

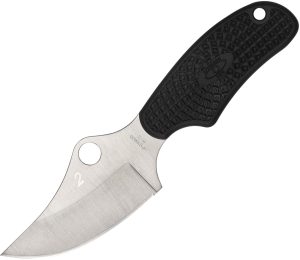

Spyderco Always Ready ARK Series Knives

The series includes the high-performance knives with blades that are designed using H-1 stainless steel with finger hole.

The Always Ready ARK is ideal for combat and personal-defense as it was designed by Army combat veteran John Shirley and his friend Sam Owens.

The FRN handles of the knives are comfortable enough to be used for a long duration.

Spyderco Aqua Salt Knife Series

This series features knives that are manufactured using H-1 stainless steel. The blades have the ability to withstand high compression and survive even after the roughest uses.

Aqua Salt knives have checkered black fiberglass reinforced nylon handles offering a secure and firm grip.

The black finishing of the knives blade complements the knife and looks classic.

Spyderco Enuff Knife Series

The series covers a wide range of fixed blade knives. These knives are lightweight which makes them an easy carry.

The blade is made of VG-10 or H-1 stainless steel and has a full tang construction.

These knives are designed for emergencies, camping, and everyday tasks.

Spyderco Enuff Salt Knife Series

These Spyderco knives are suitable to be used for hiking, camping, and many more tasks.

These knives are manufactured using the H-1 stainless steel serrated sheepsfoot blades.

The strength of these blades is commendable and withstands high compression and pressure.

The functionality is superior and provides optimum protection to excessive wear and tear.

Spyderco Moran Knife Series

This collection offers high-quality and durable fixed blade knives. The handles on these knives come in black FRN with non-slip Kraton inlays for an easy grip.

The knives come with VG-10 stainless steel blade construction that ensures durability. These knives are available with a Boltaron sheath with multi-position G-Clip that can be attached to the belt for ease of draw to the operator.

Spyderco Slipit Knife Series

The Slipit knife delivers excellent performance when these are used camping, hunting and fishing as well as many other outdoor and indoor activities.

The lightweight FRN handles on this knife are made of nylon ensuring a close grip. These blades are leaf shaped N690Co stainless steel which results in anti-corrosion properties.

Spyderco Street Knife Series

This street knife series covers a wide range of hunting fixed blade knives which are light in weight.

The Street knives are perfect for field dressing and with their black finish VG-10 stainless steel blades you can be certain about the knife’s resilience.

These knives are compact and can easily fit in the hand. These knives are designed to handle tough and precise skinning tasks as well as many other chores.

Spyderco Folding knives or Spyderco Folding Pocket Knives

This is an in-depth range of folding knives that are ideal for carrying every day. The knives in this range are different with respect to their locking mechanisms.

You will find Linerlock, lockback and even knives with Framelock mechanisms in this knives series.

Thank to Spyderco Knives, since they’re the company that presented that function to the market.

They’ve made numerous other contributions to knife style ever since, and even if you’ve never ever utilized among their knives, chances are you’ve utilized a knife that was straight motivated by one.

Thus, there is huge variety and variants available in Spyderco folding pocket knives which are as under

Spyderco Framelock Pocket Knives

The Framelock Pocket Knives in this series are made using VG-10 stainless blades that impart excellent strength and high resistance from corrosion and abrasions.

The knives have a perfect thickness and offer a non-slip grip to be used flawlessly in most demanding situations.

Spyderco Linerlock Pocket Knives

Linerlock Pocket Knives are primarily the best self-defense knives in the production line. As, these knives work on simplest liner lock mechanism.

It has a side-spring lock that allows easy opening and closing of the knife with one hand and that too without repositioning.

These Spyerco liner lock EDC knives have stainless construction offering excellent strength to withstand high compressions.

Use of G-10 handles allows the user to hold knives firmly throughout the task.

Spyderco Lockback Pocket Knives

This range of knives is known for its sleek style meant for survival and recreational purposes.

The stainless steel construction of these knives imparts immense strength and helps the knives survive in challenging situations.

The Lockback’s handles come in stainless, yellow, gray, black, or orange. Spyderco Lock back Knives work on the simple lock back mechanism i.e. the spine locking mechanism which prevents the knives from accidental opening or closing.

Spyderco Slip Joint Knives

These slip joint knives are one of the most universal types of pocket knives. A slip joint knife consists of a handle with one or more folding blades.

These blades are held in position by a strong “back spring”.

Spyderco slip joints have stainless, black, pink, red, blue, gray, or orange handles and stainless blades.

Spyderco Specialty Lock Knives

This series of knives have a stainless blades; these blades store inside the handle until its ready to be used.

The specialty lock features dual locking safety button which holds the blade safely in the open or close position.

These lightweight knives make an ideal EDC.

Spyderco Atlantic Salt Knife Series

The series covers a range of lockback folding pocket knives. The locking mechanism ensures easy opening of blade securing it in place once opened.

The handles are made of fiberglass reinforced nylon and feature a pocket clip and lanyard hole for easy carrying.

These knives are compact and can easily fit in the hand. These knives are designed to handle precise cutting tasks.

Spyderco Chaparral Knife Series

This series of knives is equipped with CTS-XHP stainless steel blade, featuring a standard edge, ensuring strength for heavy-duty tasks.

The handles are exquisite and made from Raffir Noble or solid titanium providing firm grip to prevent accidental injuries.

These knives are designed to meet the requirements of a knife enthusiast.

Spyderco Clipitool Knife Series

Clipitool Knives are the high-performance tactical knives with the ability to perform best while carrying out daily tasks.

The knives in this series have stainless steel blades some also include scissors and bottle opener that resist corrosion and completely fit inside the handle that becomes easier to carry.

Spyderco Cricket Knife Series

This series comprises of an array of lightweight folding knives, featuring stainless steel standard edge or serrated blades, providing precision in rugged applications.

The Cricket attributes pocket clip and lanyard hole creating a safe and easy to carry framelock knife.

The non-slip grip handles made of brushed stainless steel allow the users to use it for long hours without fatigue.

Spyderco Delica Knife Series

Delica Knife Series works on the manageable lockback folding mechanism. These everyday task knives are manufactured using stainless steel that resists corrosion and withstands high compression.

The knife handles are made using fiberglass reinforced nylon or stainless offered in a wide variety of colors; they convey great strength to the complete knife frame.

Spyderco Dog Tag Knife Series

The Dog Tag knives are recognized for their unique handles and blades; each handle is machined from a solid piece of black carbon fiber/G-10 laminate or aluminum with an inlaid detent spring arm making for a distinct design.

The series features strong knives that work great for box cutting, opening letters, and many other tasks.

Spyderco Domino Knife Series

The knives under this series have stainless steel blades. The Domino attributes a pocket clip for easy accessibility.

These framelock knives have red weave pattern carbon fiber front handles with titanium back handles with thumb slot and ridge for a comfortable secure grip.

These knives are worth collecting and perfect for outdoor or indoor activities.

Spyderco Dragonfly Knife Series

The series covers a wide range of lockback folding pocket knives. The locking mechanism ensures easy opening of blade.

The knives are compact and lightweight so they can easily fit in the hand. The Dragonfly knives handles are made up of fiberglass reinforced nylon with Dragonfly artwork in a variety of colors.

Thus, Spyderco Dragonfly knife series is simply designed for handling tough and precise cutting tasks.

Spyderco Endura Knife Series

This vast range of knives is known for their high-quality textured fiberglass reinforced handles available in a variety of colors.

The handles are impeccably crafted to provide a stable and secure grip while in use. The ZDP-189 stainless blades with thumb hold pull on these knives can be used for different tasks including cutting, piercing, chopping and grinding.

Spyderco Karahawk Knife Series

Karahawk Knife Series is label as the quality knives that are meant to be used by survival experts, collectors and the knife enthusiasts.

These knives have VG-10 stainless patent curved hawkbill blades.

The textured G-10 handles offers a karambit ring at the butt end for excellent hold without much straining the hands.

Spyderco Ladybug Knife Series

This favored Spyderco series includes folding knives that feature stainless serrated blades on fiberglass reinforced nylon handles, making them durable and lightweight.

The Lockback system ensures the safety of the user by keeping the blade locked during usage. The high-quality steel blades are corrosion resistant.

Spyderco Lil’ Knife Series

These folding knives are specially designed to assist you in any outdoor situations such as cutting line when fishing.

Most of the knives in this series feature form-fitting attractive G-10 handles that are textured to provide a firm and tight grip.

These knives with linerlock assisted blade opening mechanism are highly preferred for use by fisherman, trekkers, and other outdoorsmen.

Spyderco Lil’ Native Series

This series of knives is equipped with stainless steel blade, featuring a compression lock ensuring strength for heavy-duty tasks.

The handles are made from black G-10, providing firm grip to prevent accidental injuries.

These knives are designed to meet the requirements of a knife enthusiast.

Spyderco Manbug Knife Series

The series includes an array of Manbug Folding Pocket Knives with different handle patterns including green, black and yellow.

The blades made of stainless steel are strong and dependable making it easy to handle daily chores.

Light-in-weight, these knives can be easily carried around in pocket.

Spyderco Manbug Salt Knife Series

Manbug Salt Series works on the simple lockback folding mechanism. These outdoor knives are manufactured using the premium grade stainless steel serrated blades that resists corrosion and withstands high compression.

The knives have textured yellow fiberglass reinforced handles and impart great strength and grip to the complete knife body.

Spyderco Manix Knife Series

This series offers you with a selection of high-quality folding knives that are equipped with resilient stainless blades.

The stainless-steel construction provides resistance to rust and corrosion, making them durable.

All the knives in this niche are manufactured with innovation in design and accuracy; these knives deliver superior performance in outdoor situations and hostile conditions.

Spyderco Mantra Knife Series

This is purely EDC (every day carry) Knives series which includes lightweight knives with standard edges only.

The knives in this series work on the linerlock mechanism. The blades are made of CPM M4 stainless with thumb ridge, thumb hole and extended tang to survive under high compression.

The matte stonewash finish titanium handles of these knives imparts a classic look to the knives.

A portion of the sales of the Mantra will be donated to The National Parkinson Foundation.

Spyderco Matriarch Knife Series

The knives of this product series incorporate nylon handles making for a non-slip grip.

The serrated blades are constructed using stainless steel which is corrosion-resistant and denotes strength.

The knives are perfect for everyday use combat situations and outdoor activities.

Spyderco Military Knife Series

Spyderco manufactures survival knives primarily for the Military. These knives are used as official survival knives as they offer ultimate strength and sharpness.

These knives are made from stainless steel to give more rigidity and to enhance the durability.

Some of these knives are available with a black coating which prevents them from corrosion.

The handles on these knives come in a variety of colors made from G-10 making them lightweight and comfortable.

Spyderco Native Knife Series

This category of knives includes high-performance knives that are equipped with G-10 or nylon handles, making them ideal to use for heavy-duty tasks.

These knives have stainless steel blades with thumb pull hole, some serrated some standard edge.

The functional features like four position pocket clip and lanyard hole make them more desirable amongst trekkers, campers, and other outdoor enthusiasts.

Spyderco P’Kal Knife Series

This range includes a wide variety of all-purpose knives featuring black or red G-10 handles with a pocket clip.

The well-designed, ergonomic knife with wave feature which allows the blade to be opened as it is withdrawn from the pocket and thumb hole pull is an ideal safety knife.

The handles provide an impressive grip for comfortable use.

Spyderco Pacific Salt Knife Series

The series is an assortment of knives meant to cater to the fluctuating demands of the people.

Actually Spyderco Pacific Salt knife series have maximum flexibility and H1 steel blades and lock steel uses 1% nitrogen in place of carbon producing a completely rust free knife to survive under most tactical situations especially sea.

The products in this series are a great option for campers, outdoorsmen and in oceans.

Spyderco Para-Military Knife Series

With an unwavering quality and workmanship, these linerlock pocket knives are highly preferred for professionals as well as survivalists.

Some of these knives feature black finish stainless blades with thumb hole, ideal for heavy outdoor use.

This durable range of folding knives comes with a four-way reversible pocket clip, allowing safe carry.

Spyderco Para-Military 3 Knife Series

This series of knives is equipped with stainless steel blades, featuring a serrated or standard edge, ensuring strength for heavy-duty tasks.

The handles are made from nylon or G-10, providing firm grip to prevent accidental injuries.

These knives are designed to meet the requirements of a military knife enthusiast.

Spyderco Police Knife Series

The Police Knife Series includes high-performance knives with the lockback mechanism that ensures easy deployment of the blade.

The folding knives feature VG-10 stainless steel blades making the blades corrosion resistant.

These knives have textured handles which are also light weight ensuring easy grip.

Easy to carry, these pocket knives are suitable survival tools for adventurers, travelers, and campers.

Police Rescue Knife Series

Spyderco offers a wide inventory of superior pocket knives with lockback mechanism.

The Mariner style blades on the Rescue feature VG-10 stainless with thumb hole pull and lightweight fiberglass reinforced nylon resin handles.

These knives are designed to serve emergency/fire/rescue personnel, also makes for a nice self-defense tool.

Spyderco Roadie Knife Series

Uniquely designed pocket knives in this series are impeccably crafted to offer functionality.

These knives are known for their interesting stainless sheepsfoot blades with double dent opener for fingernail-free two-handed opening.

These knives are lightweight and attractive.

The nylon handles feature notched-joint mechanism and lanyard hole making the knives impact resistant and highly durable.

Spyderco Sage Knife Series

The knives of this product series have standard edge blades with thumb hole pull made of CPM-S30V stainless steel.

The knives are available in black carbon fiber or G-10 Laminate handles and include a reversible heavy wire pocket clip.

The Sage represents Spyderco’s 30-year pledge to knife crafting and learning to make better knives at every available opportunity This product is a perfect survival tool for fishing and hunting.

Spyderco Salt 2 Knife Series

The series includes an array of Folding Pocket Knives with different handle colors made from nylon.

The Spyderco Salt 2 features the lockback mechanism which offers extra security while handling these knives.

The blades are strong and dependable making it easy to handle daily chores.

Light-in-weight, these knives can be easily carried around in pocket.

Spyderco Salt Knife Series

The knives under this series combine the innovative design and high-efficiency in the folding pocket knives.

Equipped with lockback mechanism, the knives are safe and easy to open.

The stainless blade with a strong tip ensures precision and performance.

The series includes lightweight knives that are comfortable and easy to carry.

The nylon handles ensure a non-slip grip.

Spyderco Shaman Knife Series

Shaman Knife Series is an assortment of compression lock linerlock knives.

The products in this series are perfect to be used as a survival tools that can be carried while camping, trekking, and hunting.

The handles are made of textured G-10 and come outfitted with a pocket clip making them easy to carry.

Spyderco Snap-it Salt Knife Series

This category of knives includes high-performance knives that are made from H1 steel making them corrosion resistant and ideal to use for heavy-duty tasks.

The functional features like the carabiner clip make them more sensible amongst trekkers and campers.

Spyderco Southard Knife Series

The series covers framelock folding pocket knives with thumb hole, flipper and Reeve integral lock (R.I.L.) mechanism; this locking mechanism ensures easy opening of blade.

Most of the knives are compact and can easily fit in the hand. The blades are made of black finish CTS-204P steel and offer black finish titanium handles.

These knives are designed by Brad Southard and meant to handle tough and precise cutting tasks.

Spyderco Squeak Knife Series

Squeak Knife Series offers a range of folding pocket knives with black or pink fiberglass reinforced handles and non-locking N6920Co stainless steel blades.

These knives are made in Italy and feature a thumb hole and stainless wire design pocket clip.

The stainless-steel blade is resistant to corrosion and abrasion making these knives long-lasting.

Spyderco Stretch Knife Series

This series includes folding knives that feature G-10 or nylon handles with a four position hourglass clip, making them durable and non-slip.

These knives come equipped with thumb hole and jimping.

The quality ultra-high carbon ZDP-189 steel blades are impact resistant.

Spyderco Tasman Salt Knife Series

The knives of this product series have satin finish H1 steel hawkbill blades and thumb pull.

The knives are available in a variety of handles such as yellow and black textured fiberglass reinforced nylon.

The blades on these knives are sharp stainless steel some being serrated, which ensures strength and precision.

Spyderco Temperance Knife Series

Temperance Knife Series features the quality knives that are meant to be for outdoor activities and useful around the house as well.

These knives have satin finish CPM S30V stainless blades and black textured G-10 handles.

Equipped with lanyard hole and pocket clip means for these knives to be easy to carry.

Spyderco Tenacious Knife Series

The series features knives that are manufactured using 8Cr13MoV steel blade with thumb hole design.

The blades have the ability to withstand high compression.

Just like Many other Spyderco knives, these Spyderco tenacious knife series also have G-10 laminate handles, increasing a firm grip.

The finishing of the knives complements the knife body and design of the knives blades looks sleek.

Spyderco UK Pen Knife Series

UK Pen Knife series features an assorted range of knives specifically to be carried while doing daily chores as well as trekking or camping.

These folding knives are made using full-flat ground CTS-BD1 stainless steel leaf shaped blades that survives under the toughest situations.

This series lanyard hole and reversible pocket clip makes certain to be an easy carry.

Spyderco Yojimbo 2 Knife Series

This range of knives is known for their high-quality textured G-10 handles.

The handles are impeccably crafted to provide a stable and secure grip while in use.

The knives in this series features compression lock blade locking system ensuring safety when deployed.

The stainless Wharncliff blades with thumb hole of these knives can be used for different tasks including cutting, piercing, chopping and grinding.

Spyderco knives other product Categories

The list of all following products and series of Spyderco product categories which is also for sale with us.

Spyderco Axes & Hatchets

Spyderco Axes and Hatchets are slicing tools; both share comparable appearance however perform various functions.

These Axes and Hatchets comprise a carbon steel head attached to a polymer or sculpted G-10 grip.

A few of the hatchets under this are formed from a single piece of steel.

The Axes are designed to be utilized with 2 hands to make the most of striking power and can be utilized to cut wood or split firewood.

Spyderco Warrior Hawk Axe

Spyderco Warrior Hawk Series features axes with black TiNi covered D2 tool steel axe head with cutting edge.

These axes can performing jobs like splitting kindling at your base camp or hacking your escape of a crashed helicopter plus a bargain more.

The Warrior Hawk axes are developed with black sculpted G-10 handles and featured a Boltaron sheath that secures the axe from every day use and tear.

They are known for their high intense strength and resilience.

Spyderco Clothing

This series features the brand name logo Spyderco in various styles.

These T-Shirts are purposely created to be lightweight, comfortable, and fantastic for casual or active wear.

These T-shirts are crafted using premium cotton.

The best use of fabrics makes these T-shirts resilient, making sure a lasting wear.

You will find much of the T-Shirts offering the motto of the brand while some have the brand logo on the back and the front.

Spyderco Kitchen Knives & Cutlery

The company makes knives for both commercial along with low-profile cooking area knives.

The kitchen knives provide additional sharpness and strength with stainless blades.

These knives are offered with polypropylene grips which use great comfort and slip-proof grip to the users.

The majority of these blade knives are available with a storage box that ensures safe storage and transportation.

Spyderco Knife Accessories

Aside from being an acknowledged producer of innovative, Spyderco likewise provides a series of different devices including sharpener rods, ceramic stones, logo design pins, mirror decal, knife cases, lanyards and more.

The items are produced using premium raw products to use lasting efficiency.

These products are ideal for daily usage and outdoor activities.

Spyderco Baliyo

The series metal body pens with Butterfly knife type body on a lot of.

These pens are thought about reputable when it comes to editing greasy, wet or severe cold or hot situations.

The simple to open and close pens in the have features like pocket clip which keeps the pen safe from getting lost.

Spyderco Bradley Knife

The series includes the high-performance knives that are designed utilizing quality satin finish PSF27 tool steel.

The Bradley is ideal for fishing, hiking, military specialists and camping as it has a flexible blade for contouring cuts.

The G-10 grips with tubular rivets of the knives are comfy adequate to be used for a long period of time.

Spyderco Knife Sharpeners

Sharpeners are among the most essential tools that offer fast and smooth sharpening without any trouble.

These are the ceramic, stone, and diamond sharpeners, which are constructed with right angle and length.

The sharpeners are essential and handy for any knife owner to have.

Spyderco Spydero Edge Knife

This series knives that are manufactured using H-1 steel. The blades have the capability to endure high compression and survive even after the roughest usages.

Spyderco edge knives have Volcano grip texture pattern FRN or smooth Corian handles using a firm and safe and secure grip.

Some have black ending up on the knives blade which complements the knife and looks timeless.

This series includes kitchen in addition to EDC pocket knives.

buy Spyderco knives cheaper”, WE Chicago Knife Works is the best place, our prices are even lower than Amazon.

FAQ’s Spyderco Knives

Why Spyderco knives stay sharp longer?

Spyderco knows a thing or more about edges: They started as a producer of knife sharpeners before making the leap into acclaimed blades.

Some knife makers tiptoe around the subject of edge retention, but Spyderco has tackled it head on and has actually made it a key focus in all their items.

Spyderco knives go through substantial, state-of-the-art testing that thoroughly determines edge sharpness and rust resistance, which guarantees optimum toughness and performance.

Spyderco knives are also evaluated for stress, wear and tear, and ideal heat treatment.

The result is an unstoppable line of knives like the Spyderco Tenacious, a fan-favorite that never ever quits till the job is done.

What’s the offer with the round hole in the blade?

The large, round hole near the tang of many Spyderco folding knives is a hallmark feature that sets these blades apart.

The design allows for simple, one-handed opening of the knife without having to fumble for a catch or needing to tear off a nail, unlike what’s needed for some folding knives.

Note: This content is Copyrights of Chicago Knife Works. Any Spinning or re-writing will be considered Copyrights violation.

Showing 1–18 of 548 results

-

Spyderco Alcyone Linerlock (2.75″)

SKU: SC222GPGYIn StockMSRP : Original price was: $115.00.Our Price : $86.25Current price is: $86.25. -

Spyderco Amalgam Compression Lock (3.88″)

SKU: SC234CFPIn StockMSRP : Original price was: $330.00.Our Price : $247.50Current price is: $247.50. -

Spyderco Ambitious Light Linerlock (2.25″)

SKU: SC148PBLIn StockMSRP : Original price was: $136.00.Our Price : $102.00Current price is: $102.00. -

Spyderco Ambitious Light Linerlock (2.5″)

SKU: SC148PBKIn StockMSRP : Original price was: $58.00.Our Price : $43.50Current price is: $43.50. -

Spyderco Ambitious Light Linerlock (2.5″)

SKU: SC148SBKIn StockMSRP : Original price was: $58.00.Sale Price : $27.93Current price is: $27.93. -

Spyderco Ambitious Lightwt Linerlock (2.25″)

SKU: SC148PBBKIn StockMSRP : Original price was: $63.00.Our Price : $47.25Current price is: $47.25. -

Spyderco Ambitious Linerlock (2.25″)

SKU: SC148GPIn StockMSRP : Original price was: $75.00.Our Price : $56.25Current price is: $56.25. -

Spyderco Ambitious Linerlock Blue Serr (2.25″)

SKU: SC148SBLIn StockMSRP : Original price was: $136.00.Sale Price : $59.84Current price is: $59.84. -

Spyderco ARK-Always Ready Knife (2.5″)

SKU: SCFB35PBKIn StockMSRP : Original price was: $118.00.Our Price : $88.50Current price is: $88.50. -

Spyderco Assist Lockback Black (3.75″)

SKU: SC79PSBBKIn StockMSRP : Original price was: $187.00.Our Price : $140.25Current price is: $140.25. -

Spyderco Assist Lockback Orange (3.75″)

SKU: SC79PSORIn StockMSRP : Original price was: $172.00.Our Price : $129.00Current price is: $129.00. -

Spyderco Assist Lockback Salt (3.75″)

SKU: SC79PSYLIn StockMSRP : Original price was: $190.50.Our Price : $142.88Current price is: $142.88. -

Spyderco Astute Linerlock (3″)

SKU: SC252GPIn StockMSRP : Original price was: $78.00.Our Price : $58.50Current price is: $58.50. -

Spyderco Atlantic Salt Lockback Black (3.5″)

SKU: SC89SBKIn StockMSRP : Original price was: $159.50.Our Price : $119.63Current price is: $119.63. -

Spyderco Atlantic Salt Lockback Yellow (3.5″)

SKU: SC89SYLIn StockMSRP : Original price was: $159.50.Our Price : $119.63Current price is: $119.63. -

Spyderco Baliyo

SKU: SCYUS107In StockMSRP : Original price was: $55.00.Our Price : $41.25Current price is: $41.25. -

Spyderco Baliyo

SKU: SCYUS113In StockMSRP : Original price was: $55.00.Our Price : $41.25Current price is: $41.25. -

Spyderco Baliyo Black

SKU: SCYCN100In StockMSRP : Original price was: $15.00.Our Price : $11.25Current price is: $11.25.